- #INPORT TOOLS INTO SHEETCAM HOW TO#

- #INPORT TOOLS INTO SHEETCAM LICENSE KEY#

- #INPORT TOOLS INTO SHEETCAM FULL#

- #INPORT TOOLS INTO SHEETCAM SOFTWARE#

- #INPORT TOOLS INTO SHEETCAM CODE#

Automatic cut ordering to ensure that inside contours are always cut before outside contours.

Draw your part the size you want and let SheetCam work out where to run the torch. SheetCam has many useful features for plasma, laser, waterjet and oxy-fuel cutting. Some examples of specialist posts include machines with multiple heads, say a plasma cutter with a pucnch marking head. This service is normally free unless the post is particularly complicated. The programming language used is versatile enough to cope with pretty much anything you could possibly want a machine to do.Ĭustom posts can be written to your specifications. If you so wish you can create your own posts. Unlike many CAM packages the post format is freely available and documented.

#INPORT TOOLS INTO SHEETCAM CODE#

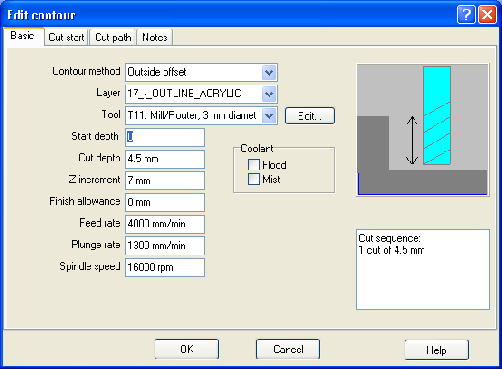

These can be fine-tuned to produce code for virtually any machine. To get over this, SheetCam comes with a wide variety of post processors. They can be flipped and rotated to make most efficient use of the material. SheetCam gives you many options to optimize cutting.įor MIlling and Routing. Once you have defined you tool you can set up the cut.

You can define as many tools as you like for different materials etc. The tool definition allows you define all of the important parameters for cutting. This is useful for machines running Mach3 for instance.

#INPORT TOOLS INTO SHEETCAM FULL#

SheetCam is suitable for milling, routing, plasma, waterjet, laser and oxy-fuel cutting.įor machines that have full control over the Z axis you can program the pierce height and cut height directly. While in Demo mode.SheetCam is a low cost but feature packed CAM package.

#INPORT TOOLS INTO SHEETCAM SOFTWARE#

The software will run in Demo mode until unlocked by a license file. If you do not receive the license file from the server within 2 hours.įreeware - sheetcam tng license. For more information on our products, please contact us at Products for CNC and motion control applications since Design, manufacturing. Over the time it has been ranked as high as in the world. If you have already purchased a SheetCAM license ensure the license is in an accessible location. Automatic license generation in Online shops is possible. Attached to that e- mail, you will find a file called license.

#INPORT TOOLS INTO SHEETCAM HOW TO#

How to install a Bruker BioSpin software license. Sheetcam License Crack.Īt no stage are you required to open the license file Mach1Lic.

#INPORT TOOLS INTO SHEETCAM LICENSE KEY#

License key definitions are stored in a text file called the license key file. If that does not work you can simply unzip the file. This download is only for users who already have a license for this version. I stole from target will i get caughtĭownloads. This section explains the structure and usage of the FLEXlm licensing file license. What is the diameter of the four circles and size of the rectangle? I wonder is Mach 3 has some assumption of acceleration and deceleration.License files are stored in the "licenses" folder within the. The lack of scale to the drawing also makes it hard to interpret. The fastest I have run my machine is IPM. I noticed only the inside corners are rounded, and only after the machine has enough distance to pick speed more than.Īs interested as I am I am not sure at least in my case how much and issue it is. Yep, same file manually edited the speeds on it. The code was identical on both runs except for the speed value. I would think that Fusion should have settings like this. This has eliminated the problem that I was having like you are. I use Sheetcam and you can set up path rules like if your hole you are cutting is smaller than a said size, the cut speed is reduced by a specified percent. I am not sure about fusion as I gave up on it a while back but you might search to see if you can set up path rules. I did not go to F I actually edited the file by hand. Is this normal or did I miss some crucial setting on Mach3? Sorry Richard, brain farted. The red and black outlines with the sharp corners were done at ipm and 50ipm, the black one with the rounded inner corners at ipm. In the photo attached, I ran a sharpie in place of the plasma. When cutting a part with many corners, I noticed that the more I increase the travel speed, the more Mach3 rounds inside corners to the point they are no longer corners.

0 kommentar(er)

0 kommentar(er)